Frequently asked questions (FAQs)

Technology & maintenance of the Electricity generating fish bypass

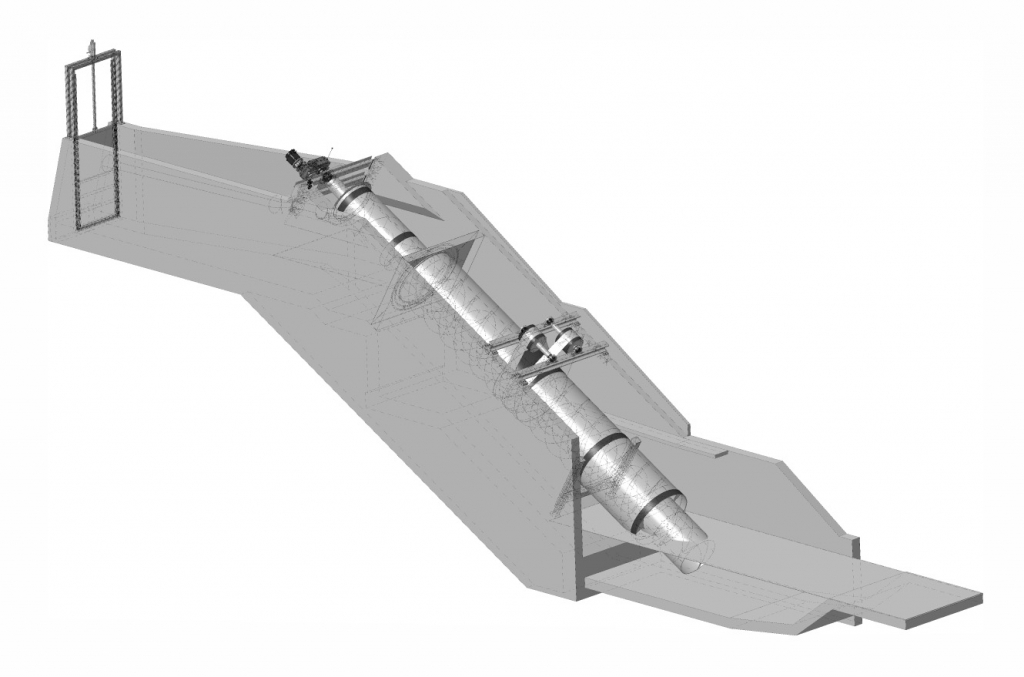

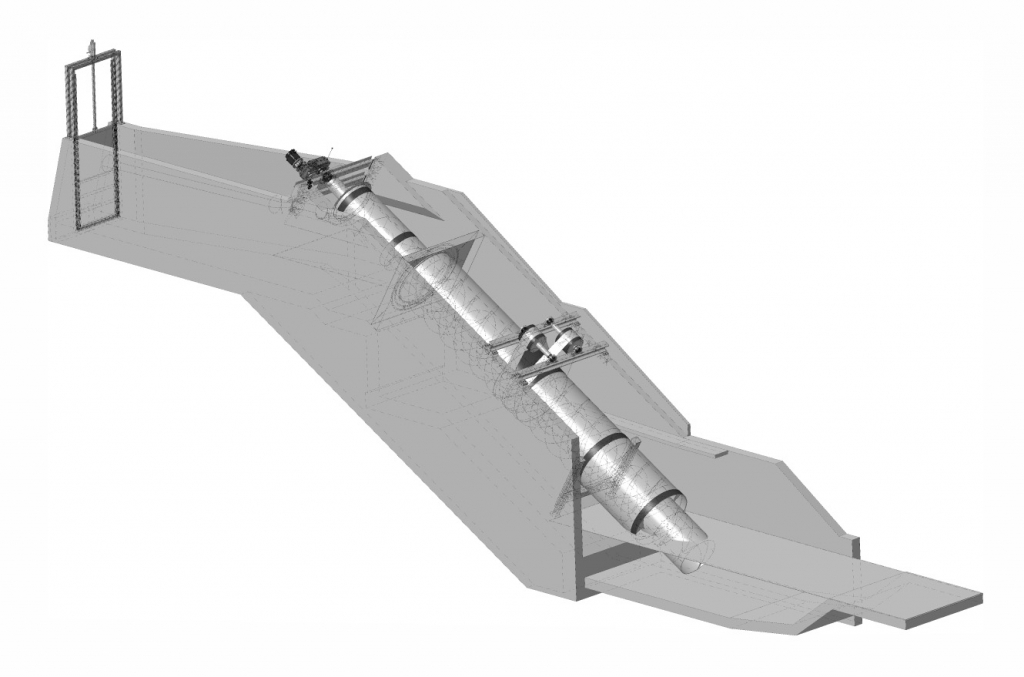

The hydropower screw with double rotating cylinders is based on the functional principle of a hydropower screw. There is an outer sheath with a headrace screw that contains an inner, counter-rotating, spiral fish transport screw, which pumps water into the headwater based on Archimedes’ Principle.

Power generation is made possible by a drum (rotating cylinder) with a casing pipe that is seamlessly welded to the screw blades. In contrast to conventional hydrodynamic screws, the Hydroconnect hydrodynamic screw is mounted by rolls on the outer shell.

The flow of water from the exiting headrace and the central luring current are used to guide fish wanting to reach the upper level to the inner fish lift. As soon as they swim into the entrance, which reaches down as far as the river bed, they are transported gently upwards in the constantly filling water. The fish end up at the upper level via a fish discharge chute.

The water transported to this upper level is ready once again for reuse by the plant or alternatively for the fish to make their way down.

Power generation is made possible by a drum (rotating cylinder) with a casing pipe that is seamlessly welded to the screw blades. In contrast to conventional hydrodynamic screws, the Hydroconnect hydrodynamic screw is mounted by rolls on the outer shell.

The flow of water from the exiting headrace and the central luring current are used to guide fish wanting to reach the upper level to the inner fish lift. As soon as they swim into the entrance, which reaches down as far as the river bed, they are transported gently upwards in the constantly filling water. The fish end up at the upper level via a fish discharge chute.

The water transported to this upper level is ready once again for reuse by the plant or alternatively for the fish to make their way down.

Besides efficient, fish-friendly electricity production, the double rotating hydropower screw makes it possible for fish to ascend and descend. Through the compact design, it is possible to install cost-effectively, even at existing hydropower plants and other transverse structures. More about this at benefits

The mechanical efficiency is up to 90%. This results in electrical efficiency, minus all the mechanical losses, of 65% even for small systems. In larger systems, the electrical efficiency increases to 70% and more.

The Hydroconnect hydropower screw is suitable for injury-free fish migration with simultaneous electricity generation. In the process it can handle the following quantities of water: 0.3 m³/s to 4.5 m³/s and heads of 2 to max. 20 m (even higher if necessary; in cascade system). The capstan makes the hydropower screw practically independent of the supply and head.

Installation sites and possible uses of the Hydroconnect hydropower screw are:

- existing dam stages

- existing power plants for fish ascent and descent incl. energy production

- run-of-river hydropower plants for fish ascent and descent

- diversion power plants as a residual water machine

- water pumping station for irrigation and/or storage power plants

- industrial process water (paper and steel industry)

- supply and drainage of sewage treatment plants (municipal + industrial)

Hydroconnects hydropower screws turn with a fish-friendly and efficient speed between 2 and 20 rounds per minute. Due to the implemented frequency converter technology, different rotational speeds are possible depending on the water flow or desired supply. Our tests have shown that fish ladders can work at a great variety of speeds. The fish adapt very well to the dynamic conditions.

The system can be used starting with a supply of 300 l/s. The highest flow rate is currently offered at 4,500 l/s. These systems are very well suited as residual water machines or as main machines for small locations. More at In use

We decided against the conventional use of underwater mounting for emission-related reasons (no grease can get into the water). The entire mass is mounted by means of heavy duty rolls. The number of rolls is determined by the total system length. The grease-lubricated guide mount in the above-water area also runs in dry air and is calculated using a long-lasting design.

The HYDROCONNECT double rotating hydropower screw is calculated for fatigue strength. The selected corrosion allowance with the choice and thickness of material ensures a minimum service life of 30 years.

The hydrodynamic screw is placed in a U-shaped concrete structure.

The space that is required is determined as follows: screw diameter + inside clearance 1000 mm total (i.e. 500 mm per side). See drawing. Protection in the bottom water area is a good idea, because that way the system can be drained in the event of high water and for maintenance work.

The space that is required is determined as follows: screw diameter + inside clearance 1000 mm total (i.e. 500 mm per side). See drawing. Protection in the bottom water area is a good idea, because that way the system can be drained in the event of high water and for maintenance work.

A trash board is not necessary, because foliage and floating debris can pass through the screw.

Due to the fact that all water life can pass through the system, fine screens are not necessary. Usually a coarse screen with bar spacing of at least 3x the width of the predominant fish species is useful and necessary.

Yes. The Hydroconnect hydropower screw can be used as an adaption to existing situations as a fish lift and/or residual water machine or for smaller situations (currently displacements of up to 4,5m3/s can be handled) as a complete replacement for a turbine.

Yes, the system will be adapted on-site specifically to your location or alternatively your conditions, depending on the head, water supply and the predominant fish species and its size.

The structure is designed for the desired HQ mark (e.g. 30, 50, 100). By means of the intake gate and corresponding outlet gate, the entire structure can be protected against high water or alternatively it can be sealed watertight. The gearbox, generator and equipment cabinet are preferably planned to be above the HQ100 line (situation dependent).

It is generally possible to operate the Hydroconnect hydrodynamic screw until the bottom water reaches its limit. Then a shutdown is required. Generally, hydrodynamic screws are quite resilient to dirt. Therefore, floating debris is not a problem. Larger trees or pieces of wood will be kept back by the coarse screen in the headwater area.

In contrast to conventional systems, the system from Hydroconnect is very space-saving. With conventional systems, a slot pass or a close to natural pool pass including a connected (residual water) screw/turbine has to be installed. The Hydroconnect hydropower screw provides the fish ascent, fish descent and use of the residual water for energy in one.

The Hydroconnect hydropower screw has the following systems for shutdown:

- Frequency converter switch

- Disc brakes (overspeed is prevented)

- Sealable intake gate

Application of the brake in the event of a power outage

As a rule, no damage to the hydrodynamic screw is to be expected, because hazards such as large logs are held back by the coarse screen. Everything else can pass through the screw and will not damage the 6-10 mm thick steel plate (depending on the system size).

No, trapping of branches or floating debris is extremely unlikely, because there are no constrictions or bottlenecks in the screw.

Categories

Your partner for ecological fish ladders

Organisation

There has not been a budget for funding fish ladders in Austria since March 2014. Before that, operators were able to request funding from the KPC (Kommunalkredit). The Hydroconnect hydropower screw system was classified as eligible for funding. Individual funding possibilities vary from state to state.

Yes, there is the possibility of applying for investment as well as electricity rate funding from the individual states, KPC Kommunalkredit or OeMAG Abwicklungsstelle für Ökostrom AG. That way, the electricity-producing fish bypass will pay for itself much faster.

The best thing is to contact your product account manager Nino Struska. He would be happy to answer your questions and help you during the planning and realisation.

The process from the first contact up to an operational hydropower screw and the approval:

- (Feasibility) analysis and evaluation of the transverse structure, water quantity – on-site inspection

- Rough concept / recommendation

- Costing

- Detailed concept / technical planning of the individual installation situation

- Financing / funding advice for the realisation of an EU WFD-conforming fish bypass including electricity generation

- Official approvals for your project

- Creation of the structure (by the customer), production of the hydropower screw with double rotating cylinders

- Delivery, assembly, trial operation

- Training of the responsible people on-site

- Maintenance, service, possibly updates

- Monitoring by a well-known institute (qualify for funding)

A truck and a heavy-duty crane provided by the customer are used for transport to your location. We at Hydroconnect take care of the clarification of the formalities and the transport. The assembly is handled by our own team as is the preparation of the control and signalling system.

It would be advisable to also make use of the outgoing turbine water currents as a luring current for the fish ladder (= on the turbine side).

The total delivery time (hydraulic steelwork) as of the written order/engineering completion: ca. 25 weeks

Umwelt & Fischerei

Each location is planned separately, and the machine size is defined according to financial and ecological criteria. Drum diameters of up to four metres are possible. Hence, this system provides up to ca. 2 metres of space (in both directions) for the predominant fish species. The screw diameter is oriented in any case around the predominant fish in the waters in order to comply with the EU Water Framework Directive (WFD 2000/60/EC).

Yes, of course. All research programmes and monitoring studies were accompanied by the Institute for Hydrobiology and Water Management (HG) at the University of Natural Resources in Vienna (BOKU). 100% freedom from injury was confirmed by BOKU in numerous studies.

Through an additional EU patent, the specially shaped double screw in the fish entry, the adapted speed of the system as well as the shape of the shell as a gap-free drum guarantee that the hydrodynamic screw with double rotating cylinders will provide 100% freedom from injury for all water life. This was confirmed by studies conducted by the University of Natural Resources in Vienna (BOKU).

No, the hydrodynamic screw with double rotating cylinders is for the passage of the strongest and weakest swimming species of fish at all stages of life. For more details, go to

Studies.

Studies.

Not only the headrace water outflow from the ascent screw but also, and above all, the central luring current that is generated by the special shape and placement of the blades in the entry area (“double screw”) serve as a guiding current.

Fish swim actively against the current into the screw and are transported gently to the headwater. For outward migration, fish and microorganisms simply swim (drift) downstream with the headrace water. At many (large) locations, an additional luring current can make it easier to find.

Fish swim actively against the current into the screw and are transported gently to the headwater. For outward migration, fish and microorganisms simply swim (drift) downstream with the headrace water. At many (large) locations, an additional luring current can make it easier to find.

No. The lower screw area is designed and patented so that it creates a luring current for fish and water life. That way the fish find the way via the fish ladder without being forced to do so.

There is a current leading to the screw in the bottom area of the entry, which is very well suited for fish and pentos that are weakened from swimming. (Also see Technology)

There is a current leading to the screw in the bottom area of the entry, which is very well suited for fish and pentos that are weakened from swimming. (Also see Technology)

Each individual fish is released into a calm zone close to the bank by means of a “fish discharge chute” (discharge of the ascended fish with a marginal slope) over the dam, protection and coarse screen. The fish continue their migration after an orientation phase.

No. It is now possible for fish to pass transverse structures voluntarily, stress-free and injury-free and to move effortlessly upstream or downstream. The natural ecological balance ensures that the fish population remains constant or rather that the populations recover again if fish can reach their spawning grounds, winter habitats and other important habitats at any time. Therefore the river life is once again autonomous and hence the biodiversity is promoted.

Even in floods, fish are not simply swept away, rather the population normalises again after a short amount of time. Fish that are swept away in a flood can return to their original locations at any time. That way the population can recover again quickly.

Even in floods, fish are not simply swept away, rather the population normalises again after a short amount of time. Fish that are swept away in a flood can return to their original locations at any time. That way the population can recover again quickly.

More than 4000 hydropower plants in Austria’s rivers have no, or non-functioning fish bypasses. Altogether, according to the ministry, there are 33,000 migration obstacles in Austria alone due to transverse structures. They must be made passable in accordance with the EU Water Framework Directive in the interest of providing environmental protection for fish. Some of these locations have energy production potential, which can be converted into valuable electricity with the HYDROCONNECT system.